Germany is Building the World’s Largest Heat Pump: Generating Energy from the Rhine River

Germany is installing a massive 162 MW heat pump that will use the Rhine River as a heat source. When the 200 million euro project is completed, it will be the world’s largest system.

In Mannheim, Germany, one of the country’s leading energy companies, MVV Energie AG, along with Strabag Umwelttechnik GmbH, is preparing to build the world’s largest heat pump. The system, which will have a capacity of 162 megawatts (MW), will use water drawn from the Rhine River as a heat source and will be able to produce heat at temperatures up to 130°C.

Set to be Operational in 2028

The project, which will be implemented with a budget of approximately 200 million euros ($231.4 million), is financed under Germany’s federal incentive program for efficient heating networks. Construction work is planned to start in mid-2026, and the facility is expected to become commercially operational in the winter of 2028.

The project will be installed on the site of the Grosskraftwerk Mannheim coal-fired power plant, which currently has a capacity of 2.1 GW. MVV Energie had previously commissioned a 20 MW river-source heat pump in the same area in 2023. The new system will have more than eight times that capacity, creating a major transformation in the company’s regional heating infrastructure.

District Heating that Can Reach up to 130°C

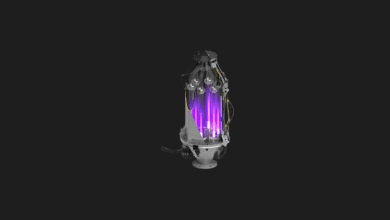

According to a statement by Strabag, the 162 MW facility, which will consist of two modules, will provide an output power of 82.5 MW per unit. These modules will use isobutane as a natural refrigerant to process the water drawn from the Rhine River in the heating process. The heat obtained by this method will be transferred to the district heating water, which can reach up to 130°C.

The water temperature of the Rhine River in Mannheim averages about 25°C in the summer and around 5°C in the winter. This temperature difference provides enough energy for the refrigerant used in the heat pump to evaporate. During the process, the river water temperature drops by 2 to 5°C.

The system’s operating principle is quite simple. The energy taken from the river water causes the refrigerant to evaporate. This vapor is then compressed by an electrically powered compressor, increasing both its pressure and temperature. The resulting high-temperature vapor is transferred via the heat exchanger to the district heating system, during which the water temperature ranges between 83°C and 99°C.

Subsequently, the refrigerant condenses back into a liquid state, then expands and cools down again, completing the cycle by absorbing heat from the river water. This closed-loop system allows for the production of a large amount of heat using a mechanism that is entirely electric and does not use fossil fuels.

You Might Also Like;

- We Selected 10 Series Similar to Stranger Things for Those Who Love It

- Where and How is Silver Used in Electric Vehicles?

- Hyundai Unveils Its Multi-Purpose Wheeled Robot

Follow us on TWITTER (X) and be instantly informed about the latest developments…