Humanoid Robots in 2025: Key Developments and Milestones

Humanoid robots continued their rapid advancement in 2025. No longer confined to laboratories, these robots began entering our homes, working in factories, and even participating in the Olympics.

2025 was recorded as the year humanoid robots significantly broke through laboratory boundaries. During this period, robots did not just learn to walk more fluidly or utilize stronger actuators; they worked on real production lines, were tested in public spaces, and evolved into physical systems interacting directly with humans.

The interest in humanoid robots is not solely due to technological novelty. The primary appeal lies in their ability to adapt to human-centric environments. Since factories, warehouses, and service areas are designed for human dimensions, doors, stairs, and shelves require specific reach, grip, and movement capabilities. Unlike wheeled or floor-based robots, humanoids can utilize these environments without extra adaptation—carrying boxes, climbing stairs, and opening cabinets. This adaptability expands the range of tasks subject to automation. So, what were the standout humanoid robot developments of 2025?

Humanoid Robots Serve as Traffic Police

One of the most striking examples of humanoid robots in public spaces in 2025 appeared in China. In Hangzhou, a humanoid robot named “Hangxing No. 1” began working like a traffic police officer at a busy intersection, directing the flow of vehicles and pedestrians. Mimicking standard police hand signals, the robot took an active role in real traffic conditions, moving in synchronization with a digital whistle sound and traffic lights. Equipped with advanced cameras and sensors, the system can detect rule violations in real-time and inform drivers or pedestrians via voice warnings.

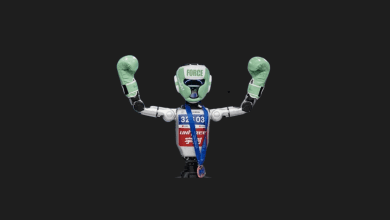

The World Humanoid Robot Games

One of the most comprehensive events where the capabilities of humanoid robots were directly compared in 2025 was the World Humanoid Robot Games held in Beijing. Organized in an Olympic format, robots competed in sports such as running, football, and table tennis, as well as scenarios focused on daily tasks like medicine sorting and cleaning. The event, attended by over 280 teams from 16 countries, brought universities and major robotics companies like Unitree together on the same stage.

While Unitree’s robots dominated the competitions, the highest recorded speed was announced as 4.78 meters per second. Although these performances still lag behind human records, the organization’s main goal was to test the limits of these systems under competitive and stressful conditions.

BMW’s Robot Workers Retire

The Figure 02 robots, which had been on duty for months at BMW’s Spartanburg facility in the USA, have officially retired. Developed by Figure AI, the F.02 robots worked on a real assembly line for 11 months, contributing to the production of over 30,000 BMW X3 vehicles and transporting tens of thousands of sheet metal parts. Images of the robots bearing scratches and signs of wear revealed that this application was not a controlled demo, but a genuine production trial conducted under heavy industrial conditions.

The trial process demonstrated that humanoid robots could adapt to shift schedules spanning months, while also clearly exposing design limitations. Figure AI announced that data obtained specifically from thermal and mechanical issues in the arm structure directly shaped the next-generation Figure 03 architecture.

The Most Advanced Humanoid: Figure 03

One of the most notable steps in the humanoid robot development race in 2025 was Figure AI’s introduction of its third-generation model, Figure 03. The completely redesigned hardware and software architecture were developed to work directly integrated with the company’s Vision-Language-Action AI system called Helix. A new high-frame-rate camera system, expanded field of view, and low-latency visual-motor control structure aim to make the robot move more stably in complex and cluttered environments. Figure AI emphasized that the shared demos did not involve teleoperation, drawing attention to the system’s autonomous capabilities.

Figure 03 is positioned as a platform designed not only for industrial but also for home environments. Soft textile coverings, advanced touch sensors, wireless inductive charging, and a more powerful sound system aim to allow the robot to interact safely and naturally within the same living space as humans.

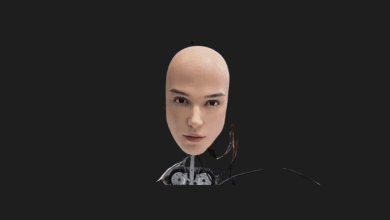

Robots with Hyper-Realistic Faces

One of the most discussed developments regarding humanoid robots in 2025 was the introduction of a robot head by China-based AheadForm, capable of mimicking the human face at an almost indistinguishable level. Videos spreading rapidly on social media showed the robot exhibiting natural blinking, gaze direction, and facial reactions, revealing how close technology has come to the “uncanny valley” border. The facial mechanism, powered by twenty-five micro-motors, a bionic movement system, and AI-supported control infrastructure, showed that humanoid robots are progressing not just physically, but also in emotional expression.

The Robot That Walked 106 Kilometers in One Go

A development pushing the endurance limits of humanoid robots in 2025 also came from China. AgiBot’s A2 model broke the Guinness World Record by walking 106 kilometers on a Suzhou-Shanghai route in a single go. During the three-day journey, the robot proceeded without ever shutting down thanks to a swappable battery system, maintaining balance and endurance across various terrain conditions such as asphalt, bridges, sloped roads, and low-light areas. Standing 175 cm tall and weighing 55 kg, the A2 performed a safe walk by obeying traffic rules with its AI-supported perception systems.

Humanoid Robots Learning Housework

One of the main targets for humanoid robots in 2025 was our homes. In this context, 1X Technologies opened pre-orders for its NEO model. Standing 168 cm tall and weighing 30 kg, NEO can autonomously perform basic household chores such as opening doors, carrying items, and controlling lights. More complex tasks can be performed via teleoperators.

Thanks to hands with 22 degrees of joint freedom and powerful motors, NEO can lift loads up to 70 kilograms. While offering four hours of use on a single charge, it can wirelessly charge its own battery when necessary. Equipped with visual recognition, voice command detection, and a memory-enabled language model, the robot can assume the role of a conversational digital companion in addition to facilitating housework. Offered for sale at a price of $20,000, it takes NEO about five minutes to empty a dishwasher and around 15 minutes to fold laundry.

Optimus Runs Like a Human

Tesla’s Optimus robots also stood out in the year we are leaving behind. In the latest update, the Optimus model demonstrated human-like running capabilities. The robot, 180 cm tall and weighing 73 kg, ran in a coordinated manner on the laboratory floor with over 40 joint movements and hands possessing 11 degrees of freedom. The shared videos revealed significant progress in the robot’s balance, gait control, and coordination skills.

While Optimus ensures efficient energy use with a 2.3 kWh battery, Tesla plans to bring the robots to mass production in the future and keep prices in the $20,000-$30,000 range.

The Robot Mistaken for a Real Person

While humanoid robots attracted attention with stage performances in 2025, Xpeng’s new generation Iron model sat at the top of the social media agenda. Standing 178 cm tall and weighing 70 kg, the robot surprised viewers with natural and fluid movements resembling a catwalk strut. Thanks to passive degrees of freedom added to its toes, Iron achieves balance and walking in a human-like manner, misleading many people into wondering if it was a robot or a human due to its realism on stage.

The robot’s hardware is supported by a biomechanical muscle system, flexible artificial skin, hands with 22 degrees of freedom, and a 3D curved screen on the head. At its heart, Iron features Xpeng’s second-generation VLA (Vision-Language-Action) model and provides 2250 TOPS of processing power with three Turing AI chips. While solid-state batteries enable long-term and safe energy use, industrial tests for the robot began in 2025, with mass production targeted by the end of 2026.

Robots Start Manufacturing Batteries

One of the developments standing out in terms of the use of humanoid robots in industrial production in 2025 was realized at Chinese battery giant CATL’s Luoyang facility. According to the company, humanoid robots working in the final testing and high-voltage connection stages of battery packs reduce safety risks while increasing production efficiency and quality. Thanks to advanced visual perception and AI systems, the robots can instantly detect differences in connection points and optimize their movements.

According to CATL, the robots provide similar speed and over 99% connection success compared to experienced human workers, while instantly detecting errors and switching to inspection mode. These systems, capable of working uninterrupted with different battery models, increase the daily workload by approximately three times compared to manual labor.