World’s First Ammonia-Powered Ship Engine Unveiled

The world’s first commercial ship engine powered by ammonia has been unveiled in Japan. The engine, which will enter service in 2026, is set to revolutionize maritime transport by reducing greenhouse gas emissions by over 90%.

Japan has introduced the first commercial ammonia engine that is poised to revolutionize maritime transport. Developed by Japan Engine Corporation (J-ENG), the engine will be used in a cargo ship scheduled to enter service in 2026.

A Dual-Fuel Revolution

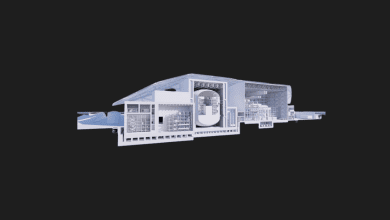

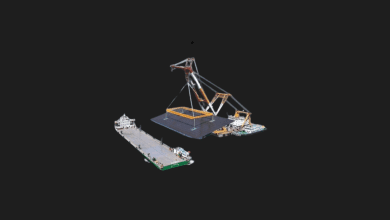

On August 30, Kobe-based Japan Engine Corporation (J-ENG) announced the world’s first commercial-scale, ammonia-powered ship engine. The engine, coded 7UEC50LSJA-HPSCR, is a notable dual-fuel design, capable of running on both ammonia and heavy fuel oil (HFO). This feature is intended to facilitate the transition from fossil fuels to renewable energy.

The engine has a 50-centimeter diameter, seven cylinders, and a high-pressure Selective Catalytic Reduction (SCR) system. This system uses catalysts and ammonia-based reducing agents, such as urea, to reduce nitrogen emissions.

Set to Sail in 2026

According to J-ENG, the engine was tested under the supervision of leading industry companies like NYK Line, Nihon Shipyard, and Japan Marine United Corporation. ClassNK, the world’s largest maritime classification society, officially certified the engine for both its environmental performance and operational safety.

The engine will be shipped in October 2025 and installed in a medium-sized ammonia-fueled gas carrier (AFMGC) currently under construction at the JMU Ariake Shipyard. When the vessel begins its commercial voyages in 2026, it will be the world’s first full-scale commercial ship with an ammonia engine.

Prior to this achievement, the company conducted over 1,000 hours of single-cylinder ammonia prototype testing at the Mitsubishi Heavy Industries R&D center in Nagasaki between 2023 and 2024. Full-scale engine tests were carried out this year.

Test results showed that even when running on a high percentage of ammonia, the engine achieved near-zero emission levels. Greenhouse gas emissions were reduced by over 90%, while nitrogen oxide emissions were cut by half compared to conventional engines. Unburned ammonia was almost completely eliminated, and thermal efficiency was equivalent to, and in some cases even higher than, heavy fuel oil systems. J-ENG also plans to develop a new 60 cm diameter ammonia engine to meet growing demand, with a target service date of 2028.

You Might Also Like;

- AI Tools Are Coming to Opera Android: Here Are the Innovations

- Top 6 Essential AI APIs for Developers to Integrate Into Your Projects in 2026

- 10 Best AI Tools on Your Phone: Top Mobile Apps for iOS & Android (2026)

Follow us on TWITTER (X) and be instantly informed about the latest developments…