The Era of Instant Creation: How Light is Replacing Layers in 3D Printing

I have spent countless hours staring at the nozzle of my 3D printer, hypnotized by the rhythmic zip-zap sound as it lays down plastic, layer by agonizingly slow layer. If you are a maker like me, you know the pain: you wait 14 hours for a print, only for it to fail at the 99% mark because of a slight temperature shift or a clogged nozzle.

That is why, when I read the latest research coming out of Tsinghua University in China, I actually sat up in my chair. We are not just talking about a “faster” printer here. We are talking about a technology that feels less like manufacturing and more like magic.

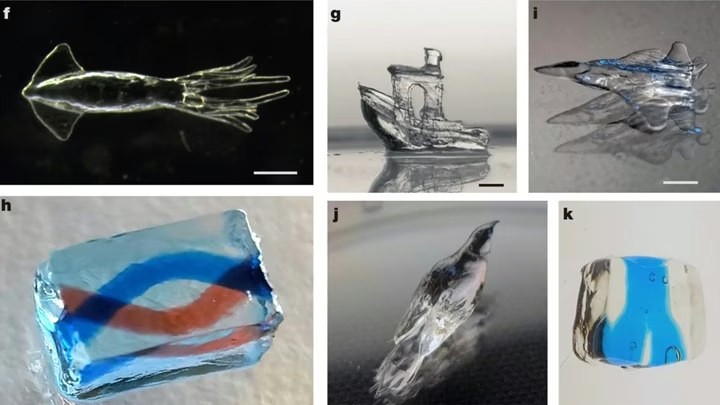

Imagine a pool of liquid. A light flashes. 0.6 seconds later, a fully formed, complex object rises from the deep. No layers. No hours of waiting. Just instant creation.

This isn’t science fiction anymore; it’s a new method called DISH, and it might just be the holy grail of micro-manufacturing.

The End of “Layer-by-Layer” Thinking?

For decades, 3D printing (or additive manufacturing) has been defined by one rule: stacking. Whether it’s FDM (plastic filament) or SLA (resin), you are essentially slicing a 3D object into 2D pancakes and stacking them up. It works, but it has limits—mainly speed and structural weakness where the layers join.

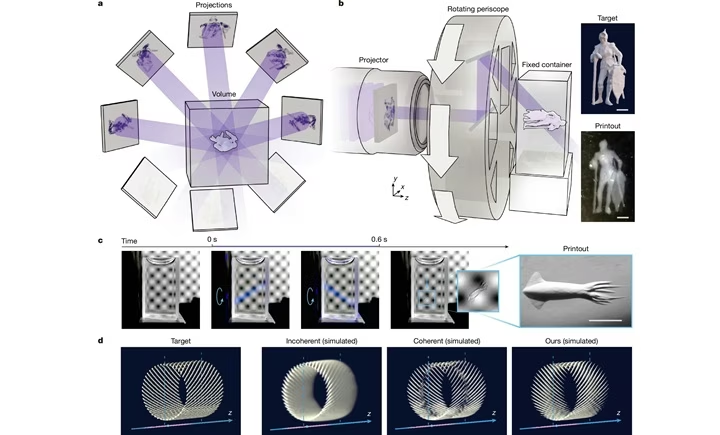

The researchers at Tsinghua have published a paper in Nature that flips this script. They have developed a system called “Digital Incoherent Synthesis of Holographic Light Fields” (DISH).

Here is the breakdown of why this is cool:

- The Old Way: You cure one slice, move the platform, cure the next slice.

- The DISH Way: You project a 3D hologram of light into the liquid resin all at once. The light hardens the entire object simultaneously.

How It Works: Spinning Light, Not Liquid

Now, “Volumetric Printing” (printing an entire volume at once) isn’t brand new. We have seen concepts like Computed Axial Lithography (CAL) before. But CAL had a major flaw: it usually required spinning the vat of resin to distribute the light.

I don’t know about you, but spinning a container full of liquid while trying to print something microscopic sounds like a recipe for disaster. The liquid sloshes, limiting precision.

The Tsinghua team solved this with a stroke of genius. They keep the resin still. instead of spinning the bucket, they built an optical periscope that spins around the bucket.

- Digital Micromirror Device (DMD): This chip creates specific light patterns (similar to a cinema projector).

- Rotating Periscope: It spins at up to 10 revolutions per second, projecting these light patterns from every angle.

- The Result: The light beams intersect in the middle of the resin. Where they cross, the energy spikes, curing the resin instantly.

Because the liquid never moves, the print is incredibly stable.

The Stats That Blew My Mind

I love diving into the technical specs, and the numbers here are staggering.

- Speed: They printed millimeter-scale objects in just 0.6 seconds. To put that in perspective, it takes longer for me to sneeze than it takes for this machine to build a complex gear.

- Resolution: We are talking about details as small as 12 micrometers. That is roughly one-fifth the width of a human hair.

- Volumetric Rate: It builds at a rate of 333 mm³ per second.

Most impressive is the depth of field. Usually, when you project light into resin, it gets blurry the deeper it goes. DISH manages to maintain a resolution of about 19 micrometers even a full centimeter deep into the resin.

Why Should You Care?

“Okay Ugu,” you might ask, “That’s cool, but I don’t need a tiny gear in 0.6 seconds.”

Fair point. But the implications here go way beyond rapid prototyping. When you remove gravity and time from the equation, you can build things that were previously impossible.

- Micro-Robotics: Imagine printing thousands of microscopic robots that can swim through arteries to deliver medicine. You can’t mass-produce those layer-by-layer; it takes too long. DISH could print a swarm in minutes.

- Bio-Scaffolds: In tissue engineering, cells need a structure to grow on. These structures need to be incredibly intricate and porous. This tech can create those complex organic shapes instantly.

- Flexible Electronics: Because the printing is so gentle (no mechanical peeling forces like in SLA printers), we can print delicate, flexible sensors.

My Take: The Replicator Is Getting Closer

We are still in the experimental phase. You won’t be buying a DISH printer for your garage next year. The setup requires precise optical alignment and specific photopolymer resins.

However, this represents a fundamental shift in how we think about making things. We are moving away from the mechanical act of “building” toward the optical act of “materializing.” It reminds me of the Replicators in Star Trek—energy converting into matter in a specific shape.

I’m keeping a close eye on this. If they can scale this up from millimeters to centimeters or even meters, the manufacturing industry is going to have a very interesting decade.

What about you? If you could print any object in 0.6 seconds, what is the first thing you would make?