Tesla Starts Building Mass Production Lines for its Humanoid Robot Optimus

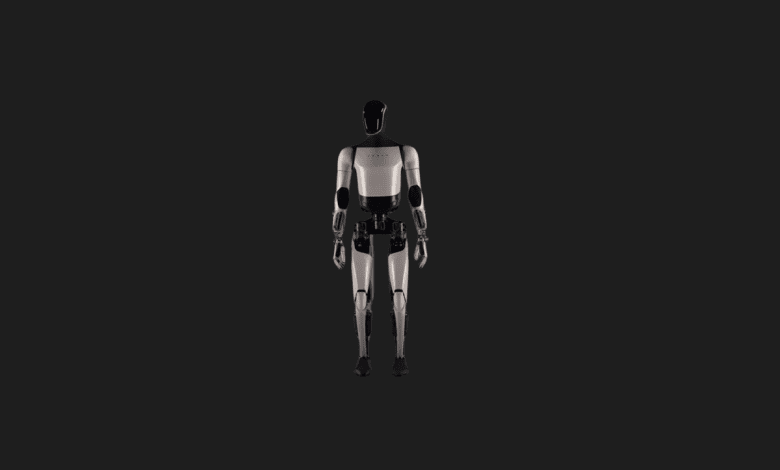

Elon Musk has announced that Tesla is very close to starting the mass production of its humanoid robot, Optimus. Having started setting up the mass production lines, Tesla aims to increase its annual production capacity to 1 million units.

For several years, Tesla has focused its attention on the Optimus humanoid robot project. However, this project is moving much slower than Elon Musk initially promised. Indeed, the company was forced to push back its mass production plans once again this year. However, during today’s investor meeting, Elon Musk reassured investors, stating that mass production is now imminent.

Elon Musk announced that the first-generation production lines for Optimus have officially started being set up. The commencement of these mass production lines signals that Optimus, which has been in the prototype stage since 2021, will soon begin to be produced in high numbers. Of course, this is true if Musk is not prematurely raising investors’ hopes again.

Tesla Aims to Produce 1 Million Optimus Units Per Year

Musk, who described Optimus as the most ambitious product in Tesla’s history, also shared clear targets for the production timeline. Accordingly, Tesla aims to start the mass production of Optimus at low volume soon, and by the end of 2026, to bring the production line to a capacity of 1 million robots per year. Musk emphasized that they will proceed step-by-step toward this ambitious goal, stating, “We plan to start production toward the end of next year, but reaching the 1 million per year level will be a gradual process.”

The real turning point in the company’s roadmap is Optimus V3, which is planned to be introduced in the first quarter of 2026. Musk claimed that this version will be much more realistic than what has been shown to date, in terms of humanoid appearance and movement capabilities, even suggesting it “might require touching it” to believe it is a robot. Unlike its traditional approach in the automotive sector, Tesla will not freeze the hardware design for Optimus even after production begins. This will allow the robot to have a structure that can be constantly updated even while mass production is underway.

However, a project of this scale is challenging Tesla with unfamiliar difficulties, even at the most fundamental level. Since a global supply chain for autonomous robots does not exist, Tesla has to manufacture many components in-house. According to Musk, the biggest bottleneck is replicating the complex structure of the human hand. This section, which requires high precision from finger joints to pressure sensors, micro-motor synchronization, and wrist movements, is currently the slowest point of the project. Due to this, Tesla has reduced its initial production target for 2025 from 5,000 units to 2,000 units.

Tesla is currently testing Optimus prototypes 24/7 at its headquarters in Palo Alto. Visitors can observe the robots autonomously navigating the building and performing simple tasks. In the short term, the company wants Optimus to become a supportive element of the workforce in its own factories, and in the medium term, to expand its commercial use by entering the external market.