Quantum Dot Greenhouse Glass: More Red Light for Plants, Higher Yield!

Quantum dot technology increases the photosynthesis efficiency of plants by changing the wavelengths of sunlight. There are noticeable increases in both plant growth and nutritional values.

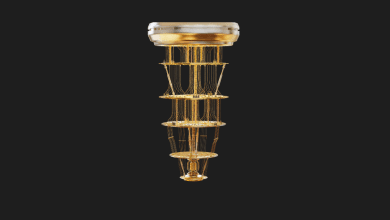

While humanity’s knowledge increases astronomically, what we are capable of continues to surprise us every day. The “Quantum Dot greenhouse glass,” which manipulates sunlight to increase the amount of red light that plants love, will provide the yield increase that we most need in agricultural products. This technology, which is the adaptation of the quantum particles used in LCD televisions to agriculture, significantly increases photosynthesis efficiency by converting blue and UV wavelengths into red. Sunlight, one of the main components of photosynthesis, is the primary requirement for greenhouses. This technology, which increases production when there is little sun in winter, could boost greenhouse cultivation in Turkey’s northern regions. Thus, fresher, less transported, and lower-carbon-emission greenhouse products could take their place in the markets. The US-based startup UbiQD has so far conducted trials in 51 different locations worldwide.

Yield Increased by Approximately 40 Percent

In the experiment conducted at the University of California, the lettuces grown under the Quantum Dot greenhouse glass showed:

- Fresh biomass weight increased by 37.8%. Plants were approximately 40% heavier, indicating significantly more edible yield.

- Leaf area increased by 38%. This resulted in more photosynthesis and mass gain.

- Root depth increased by 38%. This indicates the health and desire for growth of the plant.

- Photosynthesis power per mass increased by 41%.

- Elements needed by humans (N, P, K, Mg, Zn, Cu) increased.

- The proportion of red light increased by 61% without any loss of sunlight.

In another trial, a grower of cabbage, peppers, and cockscomb started harvesting 10 days earlier, at 9.5 weeks, instead of every 11 weeks, allowing for 5 harvests per year instead of 4.

The system, which does not require electricity, can be applied in two different ways: integrated as a laminate on the greenhouse glass, or by hanging the films in various places inside the greenhouse. The glass-integrated system offers higher efficiency. This system is expected to be launched at the end of 2028. The films used with the hanging method are already on sale. The product, sold at a price close to standard polyethylene film used in greenhouses, is already selling out. The company will start mass production by establishing a new factory in New Mexico with the $20 million investment it recently received. This is expected to lower prices further.